As reported by Gizmodo, 3D printing technology can be applied to production and construction as well as many new and interesting things.Researchers at the Massachusetts Institute of Technology are promoting a way to use 3D-printed materials to build buildings, planes and spaceships similar to building blocks.

Not long ago, a couple of MIT scientists posed a difficult question to themselves: "Can 3D printing make an airplane?"It didn't take long for them to realize that there was no realistic way to 3D print something that big, but that 3D could print thousands of small, Lego-like blocks!

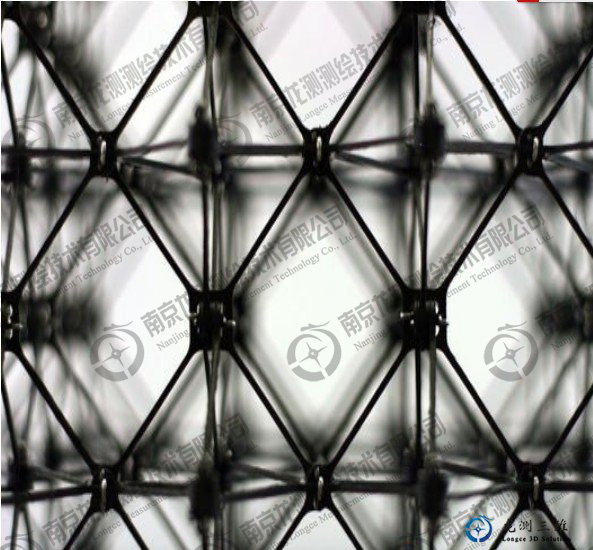

A few months later, Kenneth Cheung and Neil Gershenfeld published an article in The journal Science detailing how to use 3D printing to print a plane.Like Lego, many small, nested blocks can be linked together to form a large structure.And the whole structure can be broken down, and the blocks can be rearranged and reintegrated into another shape.This is handy when a building is damaged or when the architect wants to recycle building materials.To save manpower, Zhang and Neil Gershenfeld are also working on a robot that could replace construction workers.

The benefits of this approach are obvious, especially when large structures are being built, such as airplanes or DAMS.Building parts, or lego-like materials, can be quickly printed in 3D and reused many times.Because these parts are light and porous, the structures made of them are light in weight and easy to transport.Unlike current methods of building airplanes or spaceships, this combination of 3D-printed materials does not have to be assembled all at once in a huge hangar.You just have to put the widgets together in time.

Zhang is about to become an engineer at the American space agency, so he is likely to take the technology to NASA, where he may be able to see spacecraft built using it.