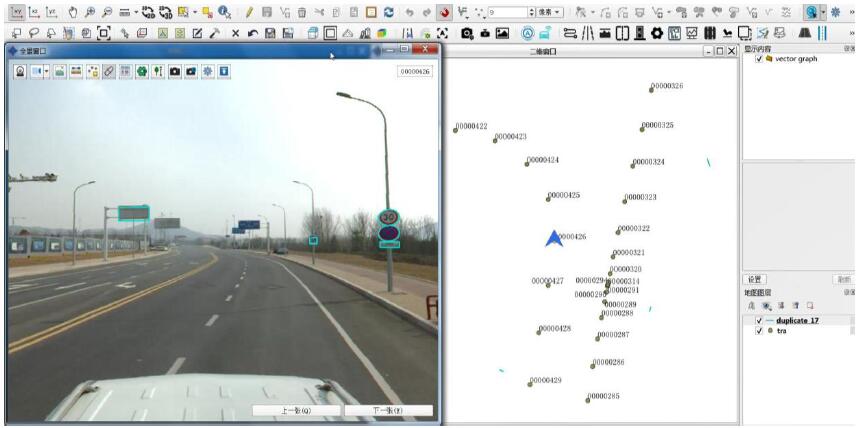

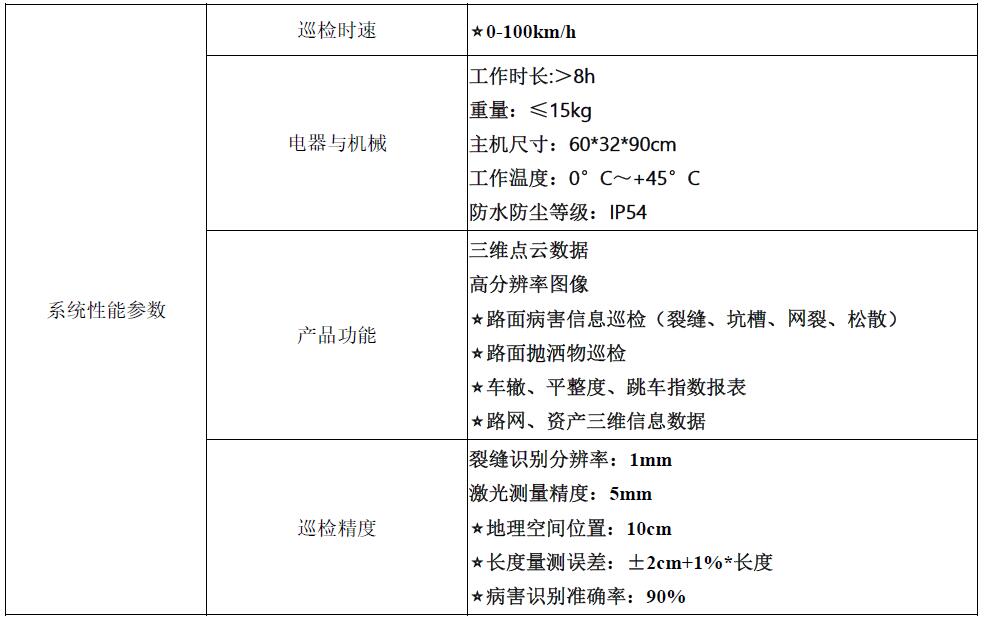

system performance parameters

Product Features

1. Lightweight and convenient: Conventional ordinary vehicles can serve as carriers for testing equipment, only requiring luggage racks. The equipment can be quickly assembled during testing.

2. Combination of patrol and inspection: This device integrates laser scanning, image acquisition, and satellite integrated navigation equipment, and achieves "patrol and inspection combination, one machine multi-purpose" based on two-dimensional and three-dimensional data.

① It can achieve real-time dynamic inspection of road pits and litters at the vehicle end, providing emergency warning information;

② It can perform intelligent extraction of surface diseases on the road surface, and detect subsidence, rutting, flatness, and jumping based on point clouds, achieving two-dimensional and three-dimensional multi-source data fusion disease analysis;

③ It can generate high-precision road network, route, and asset map information data for defect detection of signs, mileage signs, etc., achieve linkage positioning with mileage stations, and establish a spatiotemporal database of road infrastructure.

3. Fast and efficient: For the inspection of road pits and litters, real-time AI analysis algorithm is adopted. The disease identification speed can reach 10 photos per second, the inspection frequency can be more than once a day, and the detection speed can reach 100km/h. A single device can achieve 300km/d, supporting dynamic upload platform. For specialized inspections such as fine damage to the road surface, rutting, and flatness, core processing automation is achieved. Combined with some manual inspections, the comprehensive processing efficiency can reach 10km/person ● day.

4. Economical and practical: Compared with manual inspection, the comprehensive inspection efficiency is improved by 2-3 times, and the cost is reduced by more than 50%. Equipment can greatly improve inspection efficiency and quality, reduce the investment of inspection personnel, and have a high cost-effectiveness.

5. Intelligent decision-making: On the basis of ensuring the high-frequency and authenticity of data, laser measurement, photogrammetry, satellite positioning, artificial intelligence and other technologies are used to further improve the multidimensional, traceability, and reliability of inspection, providing scientific decision-making support for managers.

6. Professional customization: The system platform can be customized according to the actual situation and needs of users.

Function and achievement display

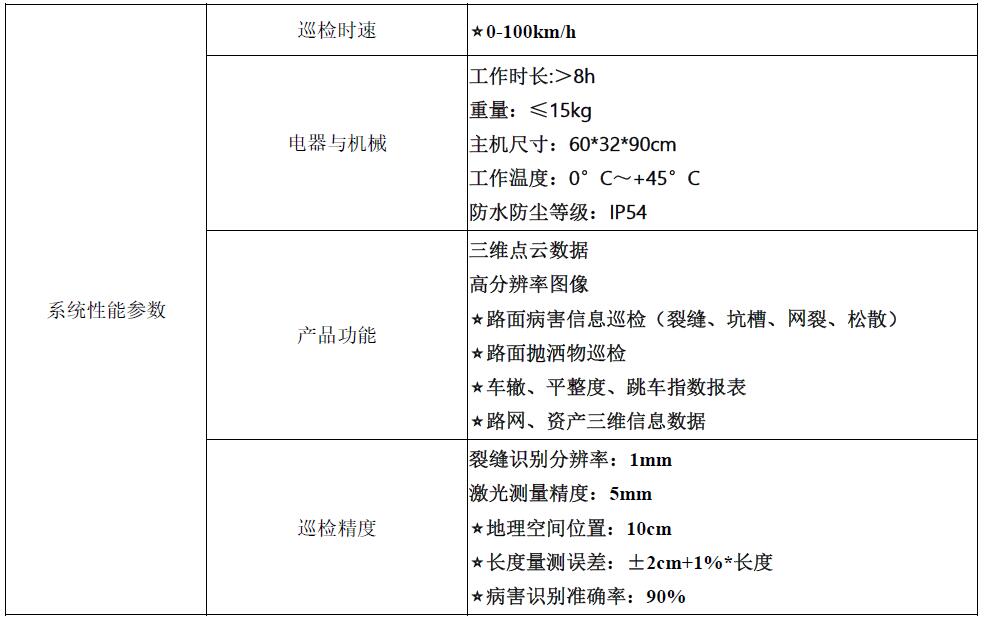

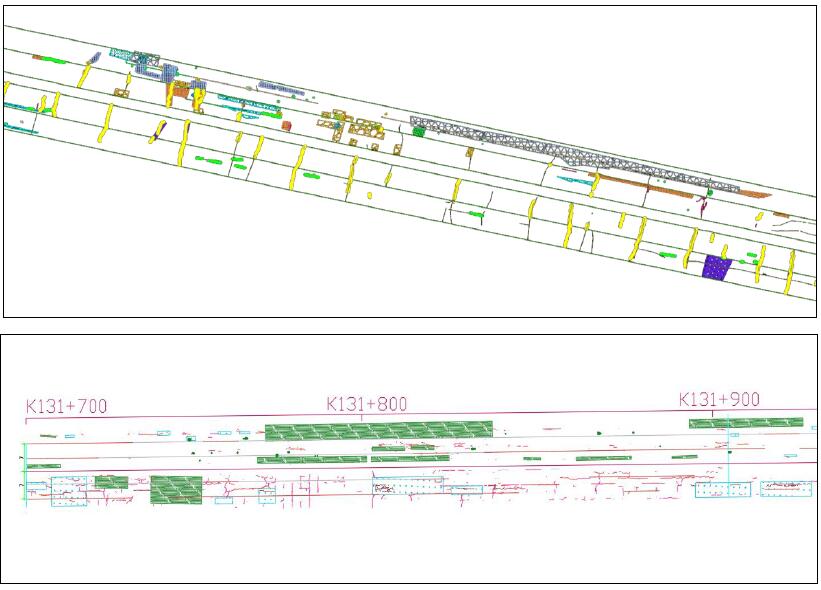

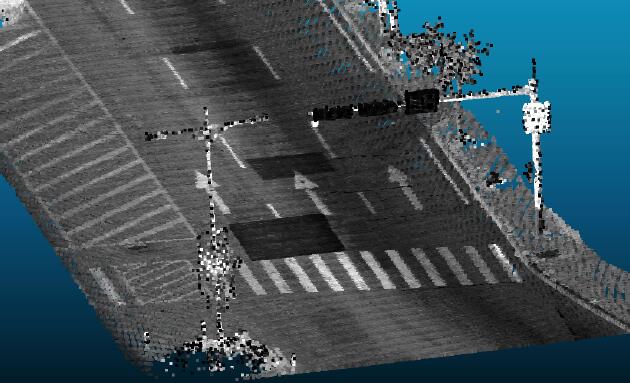

▌3D point cloud and image data

Based on integrated navigation systems, laser scanning systems, and integrated sensor calibration technology, high-precision 3D laser point cloud data is produced. Using high-precision fusion technology of multi-source data to achieve pixel level relationship matching between point clouds and images, supporting accurate mapping of image recognition targets.

3D point cloud of roads

Road foreground image

Foreground depth image

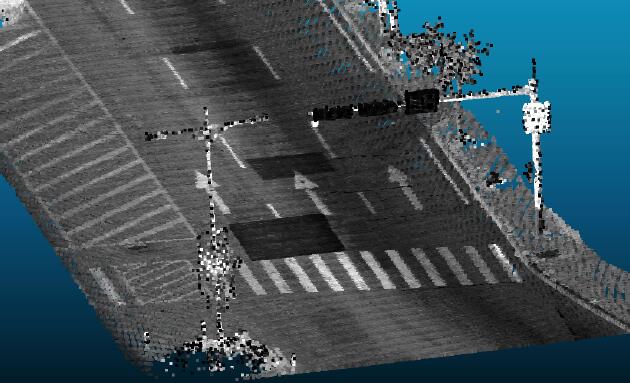

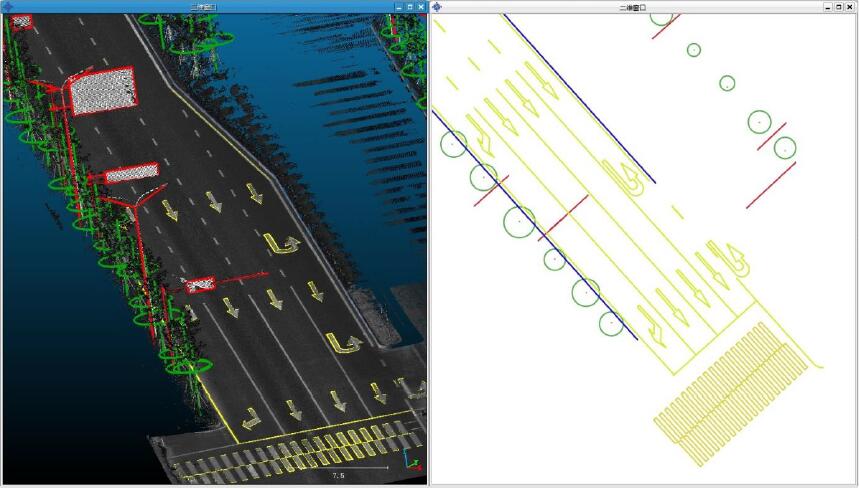

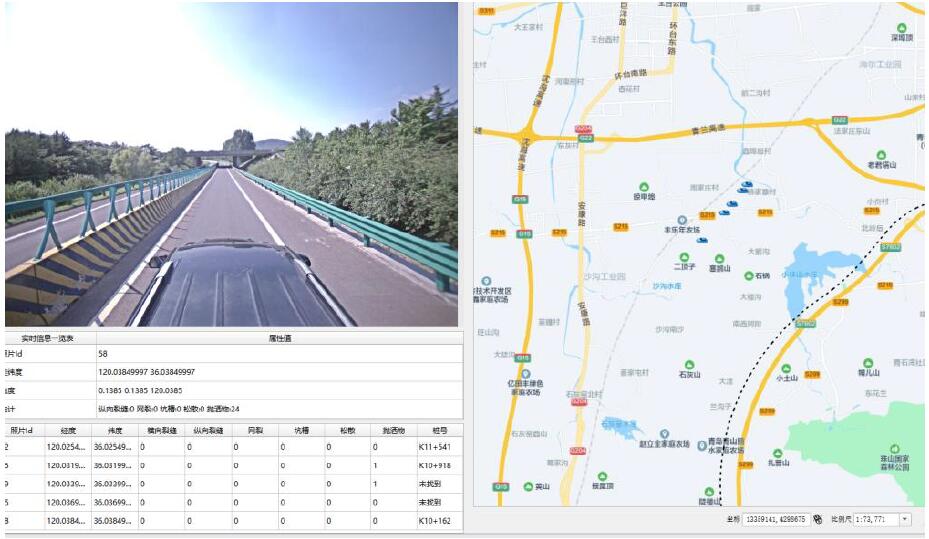

▌Asset information collection, inventory, and inspection

The 3D information collection function of road assets integrates multiple independently developed road target feature extraction algorithms, achieving semi-automatic extraction of 3D features of road facility assets such as long and short marker lines, directional arrows, curbstones, artificial poles, signs, and street trees.

We have conducted change detection on the information of damaged facilities such as signage, mileage signs, and columns, achieving intelligent recognition of facilities and 3D position restoration. Based on the background asset foundation database, we can achieve comparative analysis of multiple defects.

Road All Element Asset Basic Database

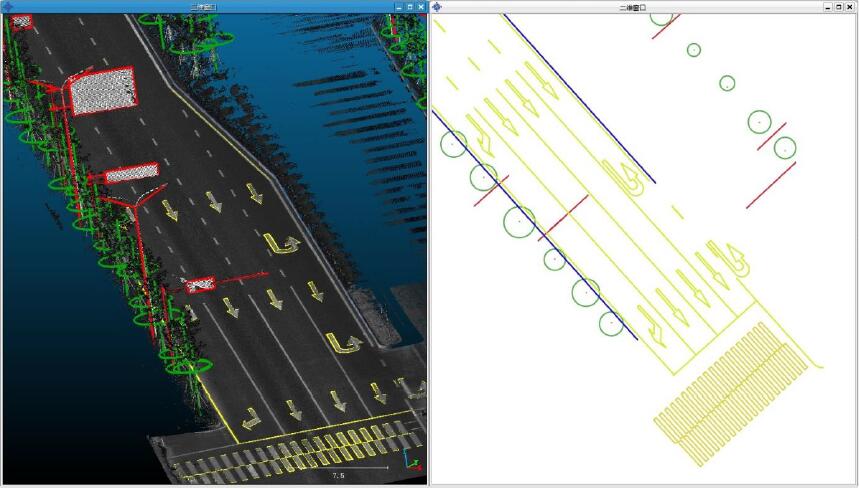

Realistic view of road assets

Intelligent identification and detection of signs (pillars), kilometer stakes, and hundred meter stakes

▌Road surface disease inspection, identification and positioning

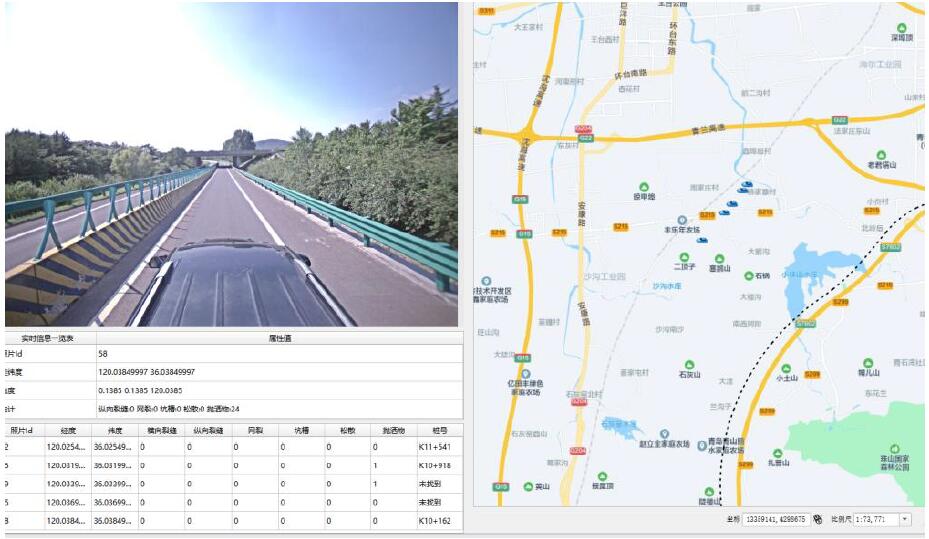

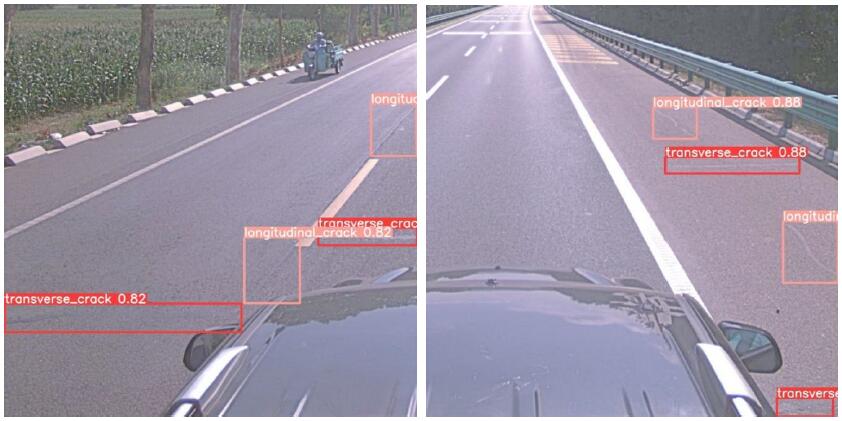

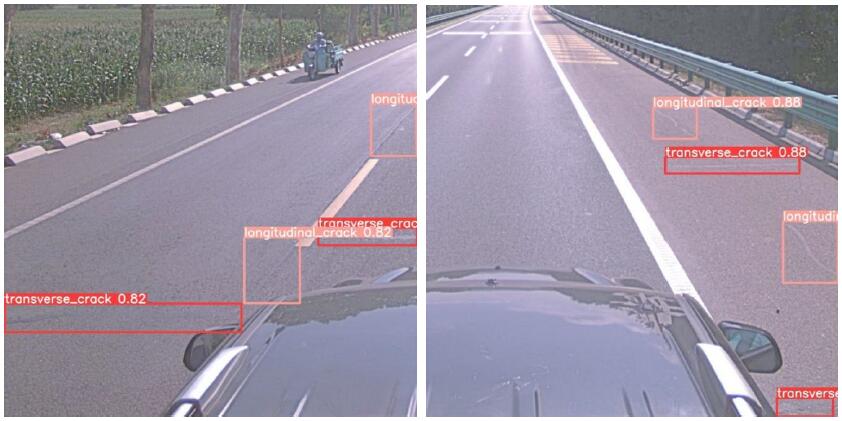

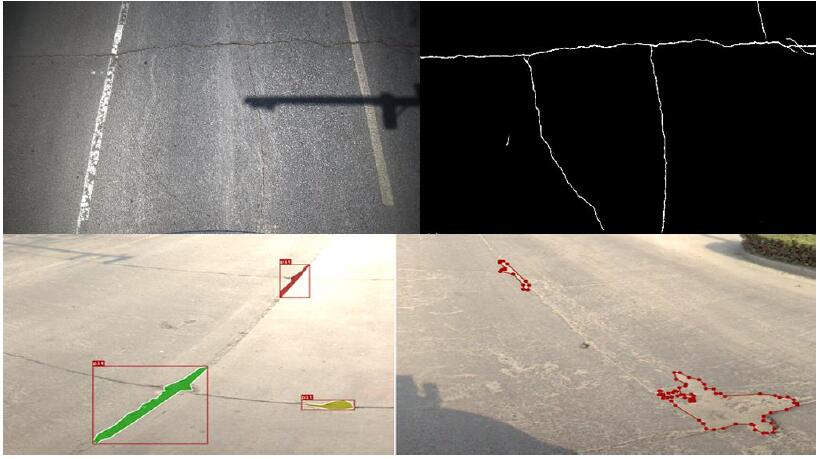

Real time analysis at the vehicle end: Utilizing deep learning algorithms to automatically identify and map locate disease targets such as cracks, potholes, mesh cracks, and looseness, achieving real-time analysis and processing at the vehicle end with an accuracy rate better than 90%.

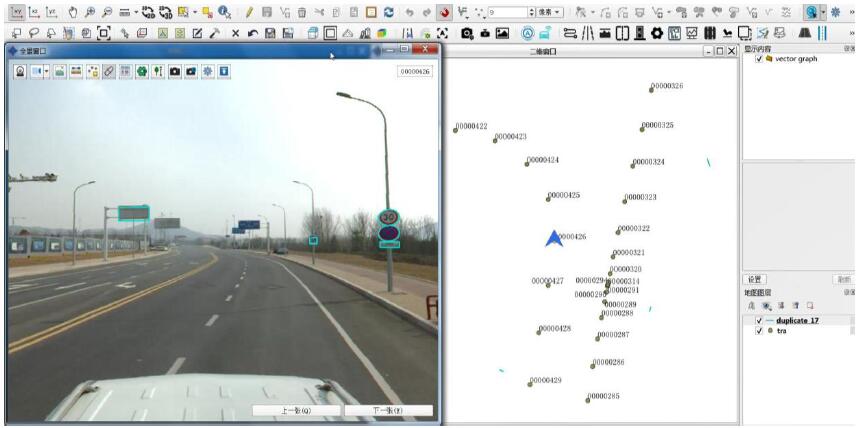

Real time analysis and preview of vehicle end disease identification

Identification and localization of road surface diseases

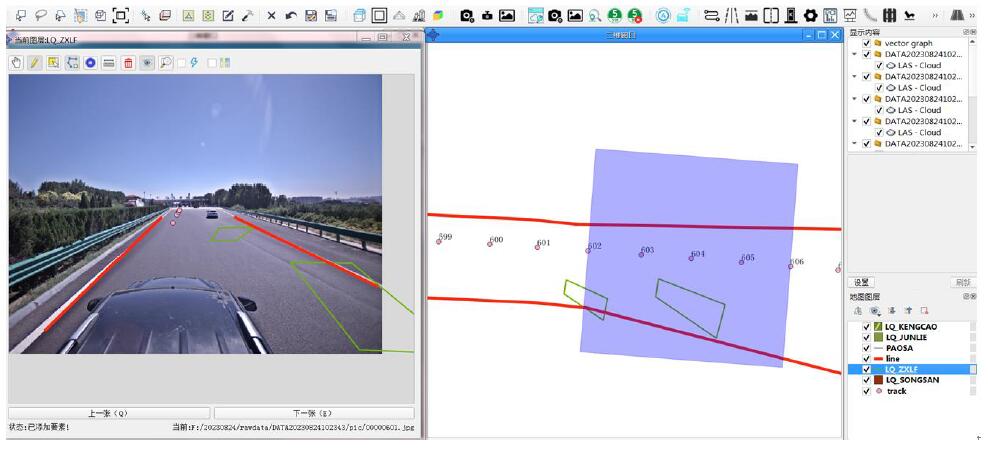

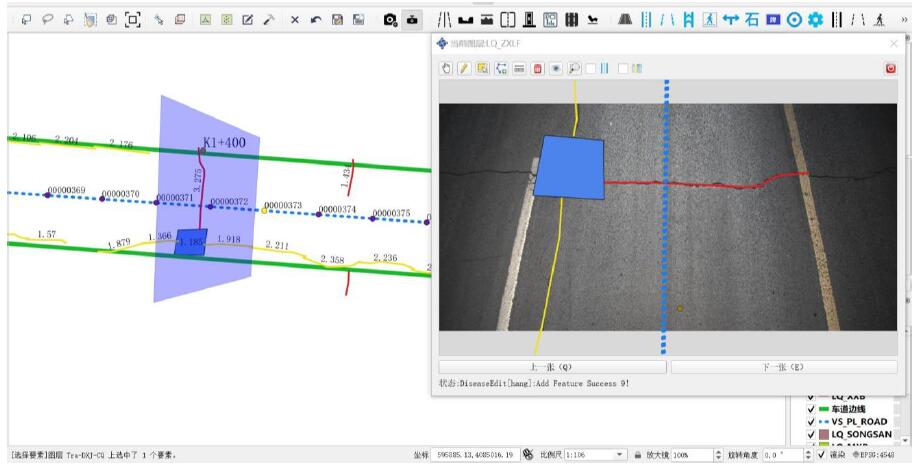

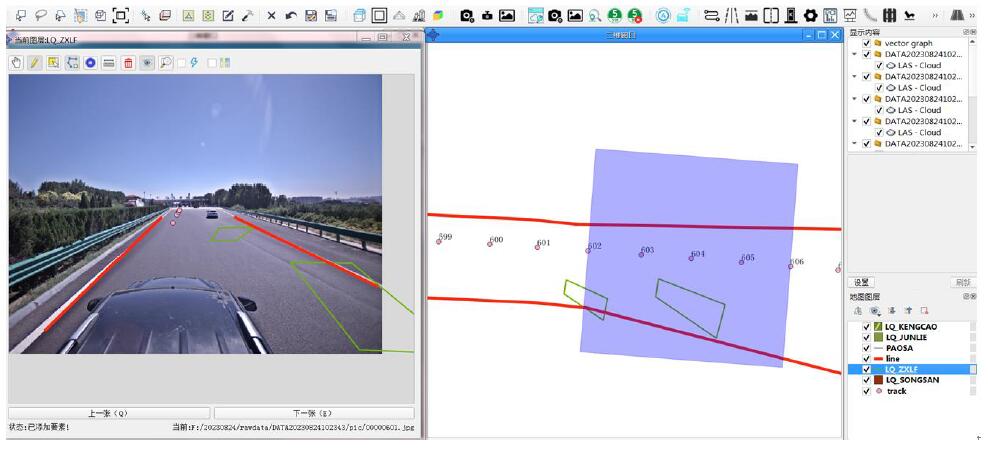

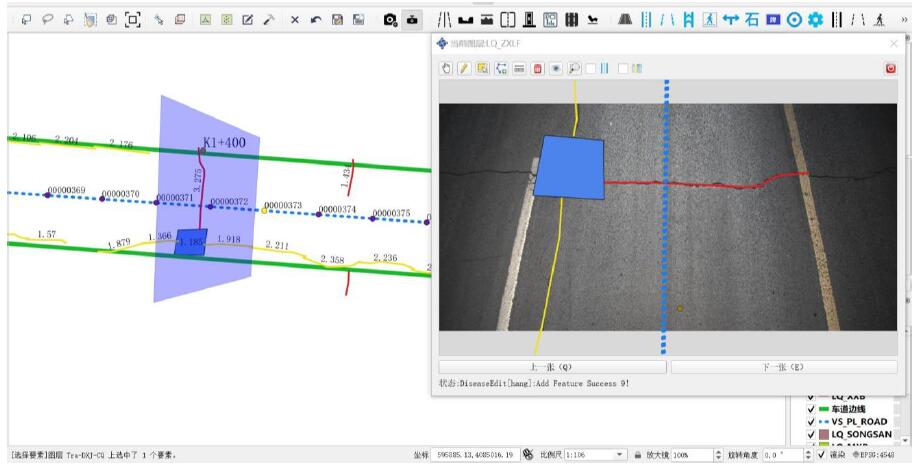

Software post-processing: The road disease inspection and processing software provides a fast processing function for road diseases based on multi-source data such as 3D point clouds and road images. It supports manual interactive inspection, modification, statistical report output, and other functions for road diseases, and supports the output of road disease distribution maps.

Road disease inspection and processing software (2D and 3D real scene inspection)

▌Inspection, identification and positioning of spilled materials

Real time analysis at the vehicle end: Utilizing deep learning algorithms to automatically recognize and map locate spilled objects, achieving real-time analysis and processing at the vehicle end with an accuracy rate better than 90%.

Identification and positioning of road surface litters

▌Road surface disease detection and mapping

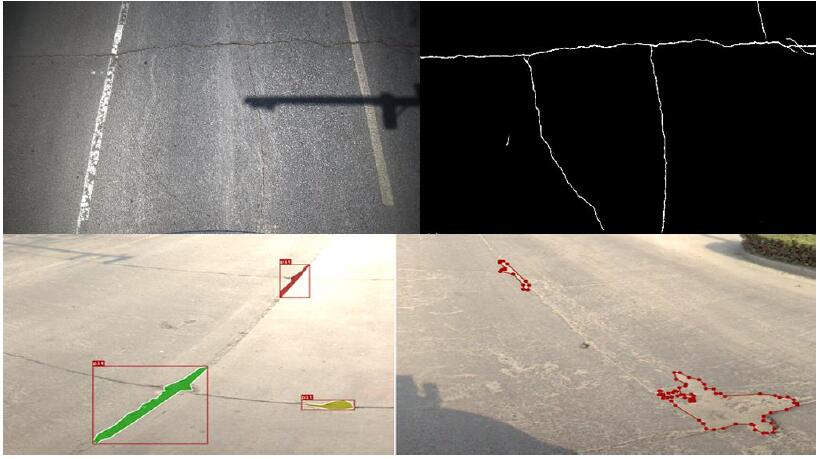

The software supports semantic segmentation algorithms for deep learning of cracks and potholes, automatically detecting fine vector features of cracks, grouting cracks, and potholes in road surface images, with an automatic recognition accuracy of 85%. It provides symbol display of road surface disease maps and supports interactive disease inspection and editing functions. It uses calibrated measurable images to link diseases and interactively extract disease vector features.

Semantic segmentation effect of deep learning for cracks and pits

Vector distribution map of road surface diseases (GIS+CAD)

Interactive modification of measurable image diseases (rear view)

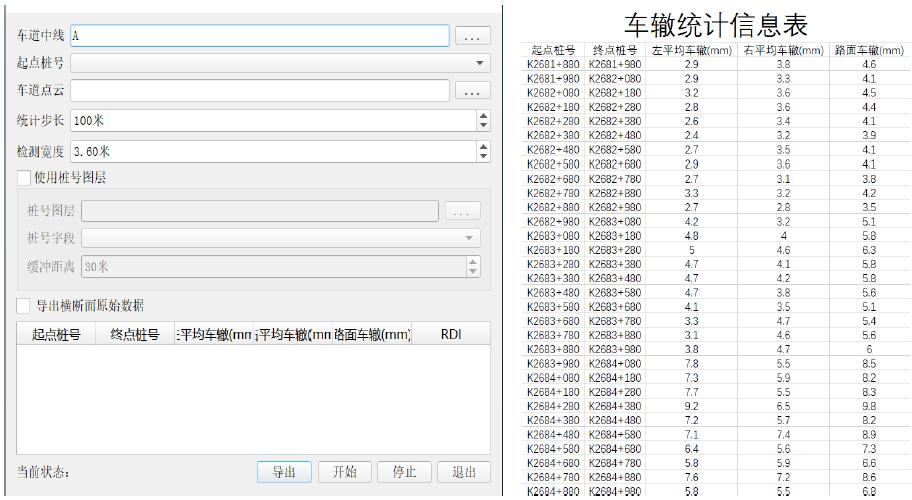

▌rut detection

The supporting rut analysis function of the system can calculate rut depth, length, and other information based on the road surface point cloud, and output results at any interval.

Rutting calculation

▌evenness inspection

The supporting flatness analysis function of the system calculates flatness based on the point cloud of the fully covered road surface of the lane, and can output flatness statistical results for multiple longitudinal positions of the road surface.

Flatness calculation

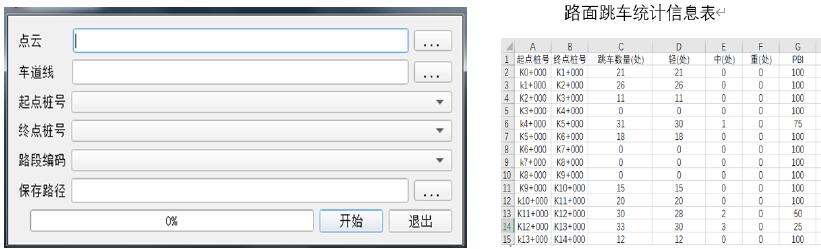

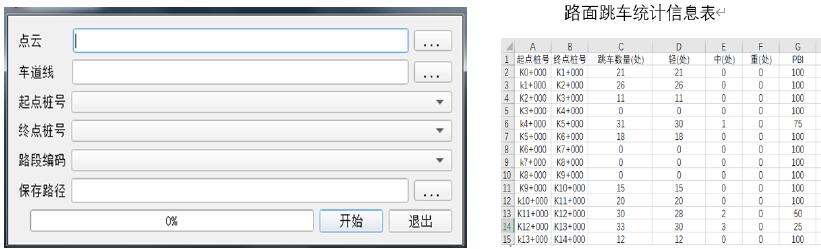

▌Trip detection

The system is equipped with a skip analysis function, which calculates the road skip index based on the fully covered road point cloud, and can output the number, degree, and PBI index of trips per kilometer for multiple road positions.

Trip calculation

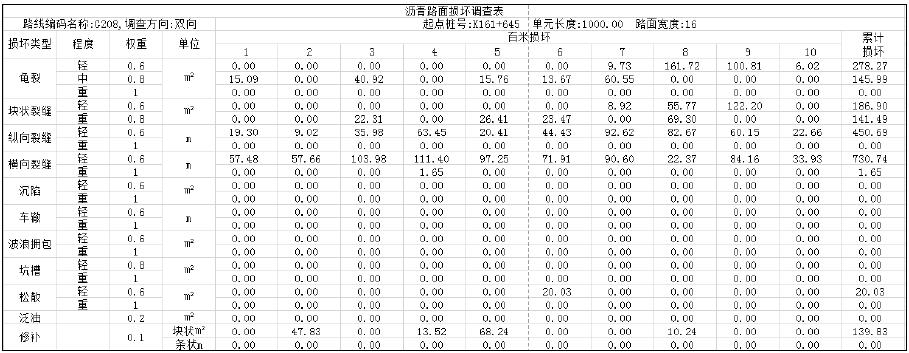

▌Standardized report output

Based on the disease detection results, road surface diseases can be classified and counted, and the road surface damage rate (DR) and road surface damage condition index (PCI) of the road section can be calculated, and the report can be output in a standard format.

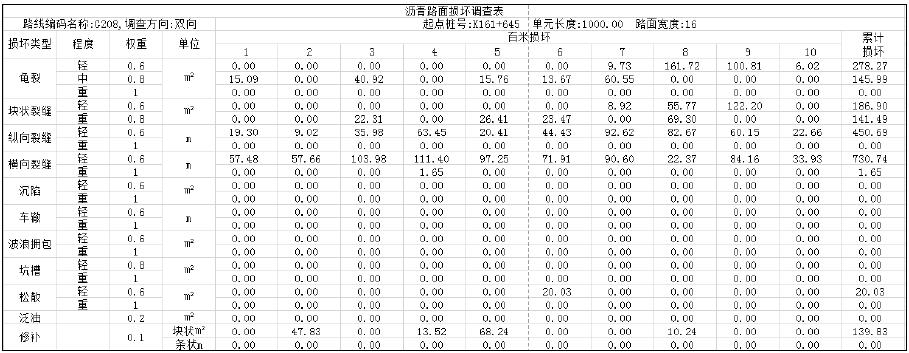

路面损坏调查表

Pavement Damage Index Evaluation Table