The Creaform HandySCAN 3D series is known as a benchmark product in the portable metrology grade 3D scanner industry, with recognized, mature, and reliable technology.

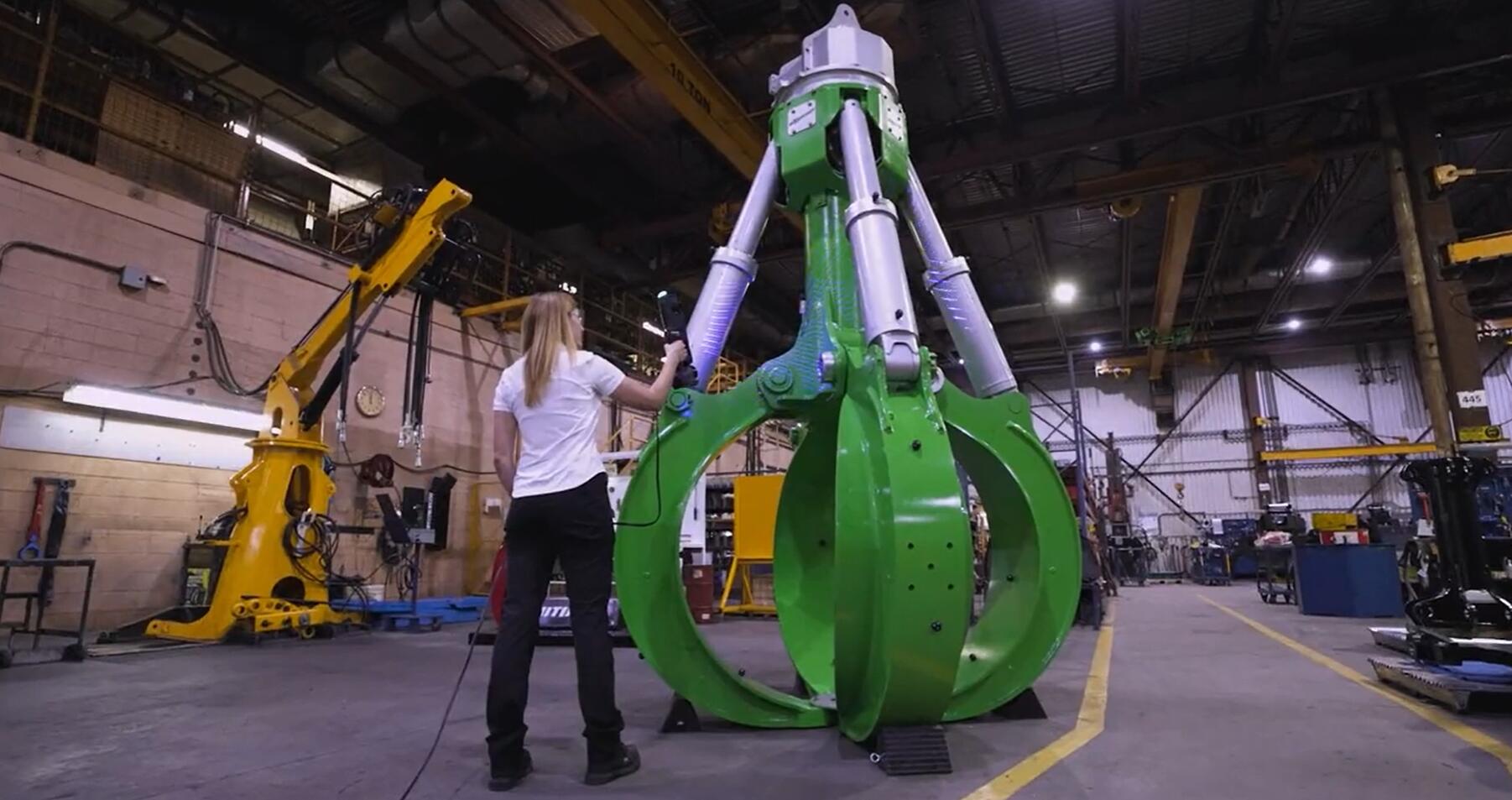

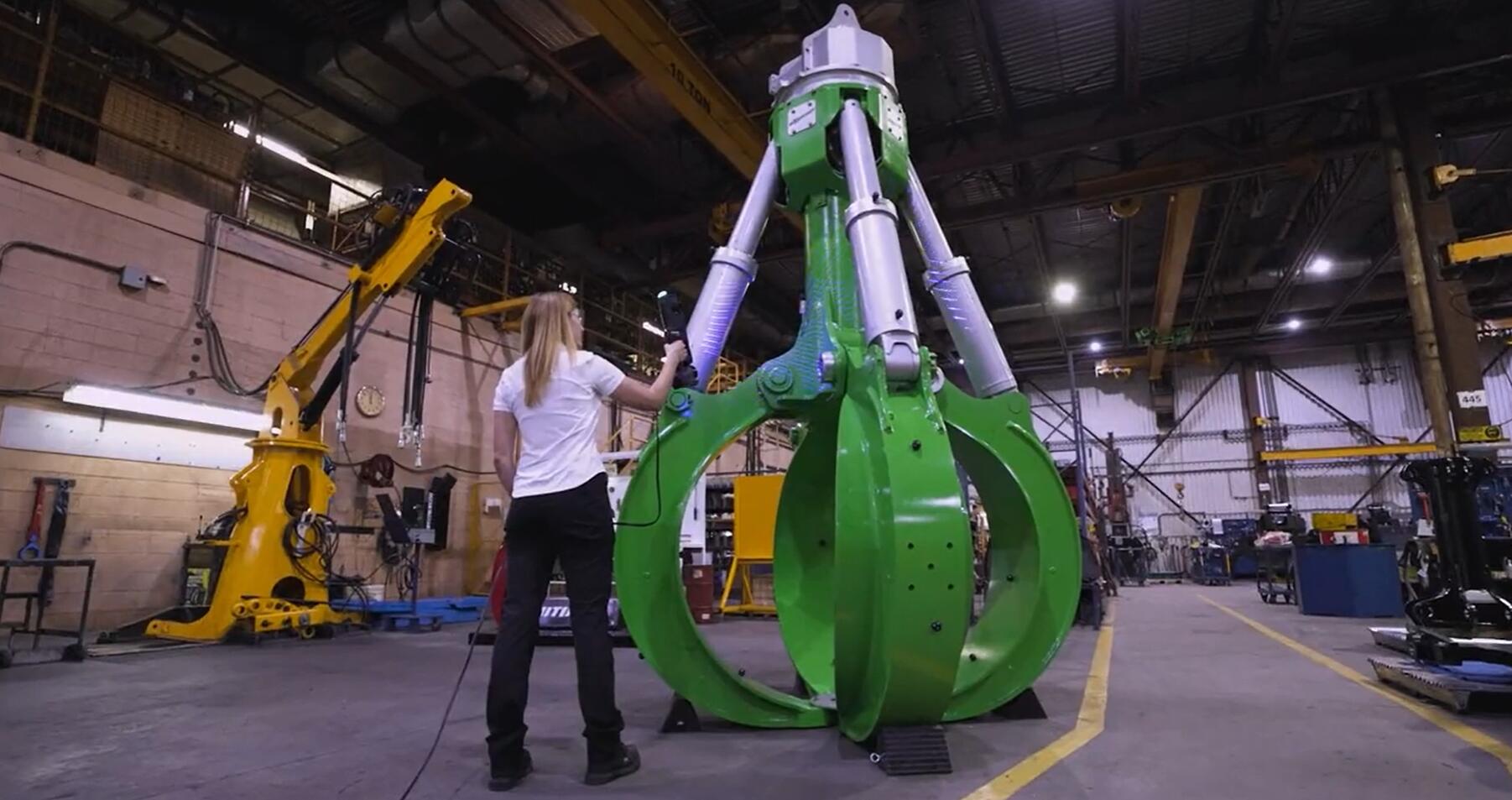

The all-new MAX series inherits the original advantages of HandySCAN 3D, combining portability, accuracy, high speed, and easy operation. And after optimization, it can perform high-precision 3D measurements on common large and complex components in industries such as aerospace, transportation, energy, mining, and heavy industry.

The HandySCAN 3D | MAX series can capture exquisite details and scan large objects, empowering professionals to easily scan large components and components, and obtain high-quality 3D scanning results in just a few minutes.

Product features

Suitable for large components

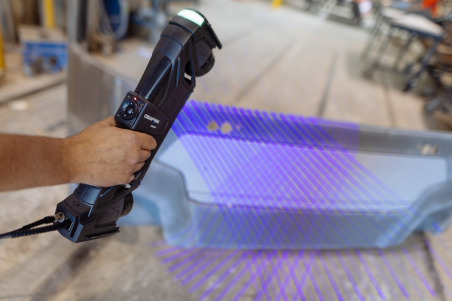

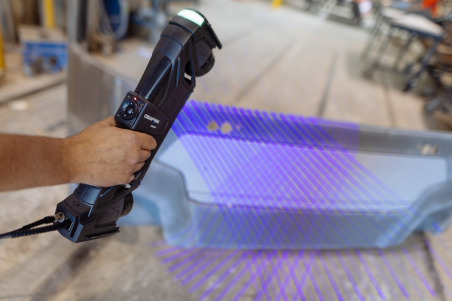

The HandySCAN 3D | MAX series is equipped with 38 laser lines and a large scanning area, making it ideal for measuring large components (up to 15 meters). It is fast and easy, and can obtain measurement level results in just a few minutes.

This handheld 3D scanner has a flexible measurement range feature (Flex Volume), enabling users to measure large components at higher speeds at longer distances, and can also flexibly measure small components at close distances (less than 1 meter) in a way that enhances scanning quality.

● Quick setup and scanning process

● Wide measurement range and expandable volume

● Instant grid and ready to use files

High precision and resolution

This 3D measurement solution has dynamic reference and volume accuracy optimization functions, and can work in harsh environments. Regardless of the user's experience level, it can perform high-precision measurements on large components.

Its flexible measurement range feature (Flex Volume) can also obtain high-quality details of components up close with higher accuracy. The MAX series, with its real-time calibration function, integrates calibration steps directly into the scanning workflow, automatically and seamlessly performing calibration for users.

● Measurement accuracy is almost unaffected by environmental instability

● Certified to ISO 17025 and compliant with VDI/VDE 2634 Part 3 standard

● Integrated photogrammetry

● Collect exquisite details

Widely used and simple to use

The HandySCAN 3D | MAX series can detect various types of surfaces, including bright, glossy, and even reflective surfaces, without the need for surface treatment or any component preparation work.

The intelligent surface algorithm function, with its advanced algorithms and image processing technology, can optimize surface measurement, provide better performance, and better capture surfaces with strong contrast between light and dark that are difficult to measure.

It is also equipped with artificial intelligence (AI) to achieve high-quality tracking, providing users with a flawless and simple scanning process.

●Blue laser technology

●Real time grid visualization

● Plug and play

Technical Parameter

Technical Parameter

Application area

Quality control

The HandySCAN 3D | MAX series meets the quality standards of industries such as aerospace, transportation, energy, mining, and heavy industry that frequently deal with large components and components.

Reverse engineering

The MAX series not only meets the requirements of product development for speed and high resolution, but also has extraordinary portability, making it very suitable for measuring large components that are difficult to move.

Non destructive testing

The HandySCAN 3D | MAX series can work well with VXintegrity, requiring fewer target points compared to the BLACK series, making it an ideal 3D scanner for measuring large structures such as pressure vessels.