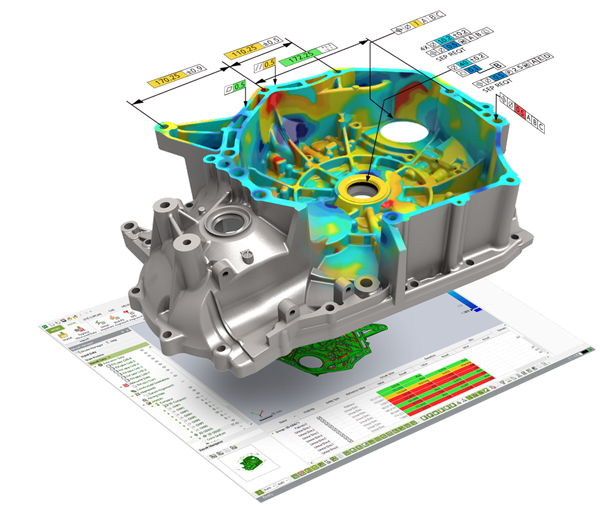

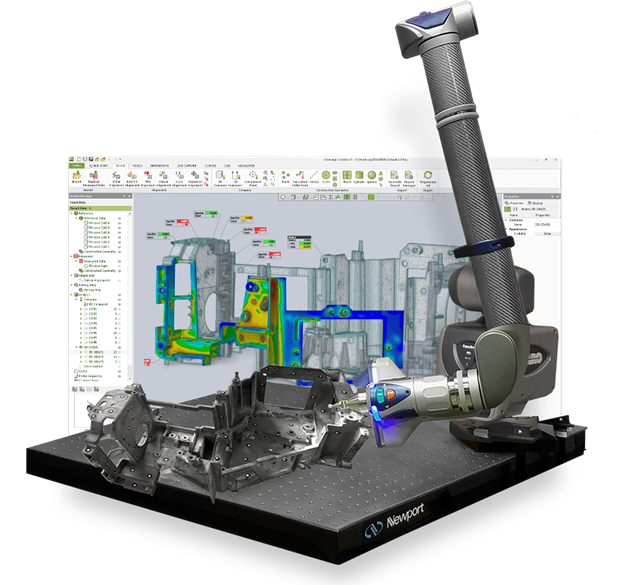

Geomagic® Control X™ is a professional 3D quality control and dimensional inspection software that lets you capture and process the data from 3D scanners and other portable devices to measure, understand, and communicate inspection results to ensure quality everywhere.

Inspection isn’t just for metrology specialists. Geomagic Control X empowers everyone to measure, understand, and make decisions about their parts faster, more often, and more completely—from anywhere.

-

Ensure quality everywhere. Bring the power of 3D scan-based inspection to more people in more places with software that makes it easy to both capture and interpret scan data.

-

Gain deeper insights beyond pass/fail. Scan parts to capture more information and leverage rich data to understand why parts are in or out of tolerance.

-

Optimize manufacturing processes. Recognize and address issues faster with insights gained from comparing scanned parts to CAD models or golden parts.

-

What Can You Do with Geomagic Control X?

Geomagic Control X includes features to help you ensure quality for each stage of your manufacturing workflow including designing, manufacturing, inspecting, and maintaining.

-

Design

-

Design for manufacturability.

-

Find and fix problems.

-

Manufacture

-

Identify and resolve manufacturing and assembly issues.

-

Eliminate costly scrap and rework.

-

Inspect

-

Solve your toughest measurement problems.

-

Improve quality documentation.

-

Reduce quality control bottlenecks.

-

Maintain

-

Assess damage, deformation, or wear accurately and consistently.

-

Predict part failure before it happens.

What’s New in Geomagic Control X?

Geomagic Control X 2020 gives you simple and powerful inspection capabilities leading to better decision making, improved efficiency for inspection workflows, and lower overall risks and costs.

It focuses on making the inspection process easier, allowing access to everyone who participates in the inspection process, and enhancing features to provide greater productivity in metrology workflows.

-

New and updated portable CMM workflows

-

Direction tolerances

-

Inspection viewer

-

Simulated CMM point clouds

-

Object annotations

-

Deviation location update

-

Automation server update

-

3D Sprint® file support for 3D-printed build inspection

-